Three Methods Used to Pleat Fabric

There are three basic methods used to pleat fabric: hand, pattern and machine. These methods can be used individually or in combination in various ways to yield different results and textures.

1. Hand Pleating – This method uses hand folding a piece of fabric, pleat by pleat. There are also other hand pleating methods such as shibori, which employs the use of ropes to bind and compress the fabric.

Hand pleating, fold by fold, becomes much easier with tartans, plaids or striped fabrics since the repeat in the fabric is used as a guide to assist in the folding as seen below.

Image courtesy of CMStewartWrite.

Today, this process of hand pleating is still practical, but only in certain circumstances. Below is an example of hand pleating being draped over a dress form for a particular style. This is most commonly used during the design process when a designer is experimenting and draping over a form. If the dress will be duplicated, a special pattern can be created which will shorten the production time.

Image above courtesy of Esayel

When pleating the bodice of a dress and the desired effect will be very contoured around the body, a seamstress will pin the pleats one by one to the dress form with a piece of bias fabric. This side pleated bodice (below) is an example of difficult hand pleating and cannot be duplicated by machine or pattern pleating.

Image above courtesy of Nasya.

2. Pattern Pleating – This method of pleating employs the use of a cardboard pattern or a tool referred to as a “pleaters board.” Pleating boards are still used and sold today but mainly for the home sewer. When using a pleating board, the fabric is stuffed into spaces and then pressed with a steam iron.

Below is an example of a DIY pleaters board (for instructions how to make one visit Lex). They are fairly simple to make but can be rather limited in use. I can understand using them for smaller fabrics or trimmings, but for larger projects like skirts or dresses, they can be very cumbersome. Also, you may start pleating the fabric off the grain if you are not very careful. When that happens your seams will be very difficult to sew because of puckering and your pleats can start to curl. If you want to do everything yourself then my advice is to go for it. However, the pleat you will make with a pleater board is so basic yet at the same time very difficult. It would be much easier for you to bring us your fabric and we’ll pleat it for around $10 dollars per yard (depending on the fabric).

Image above courtesy of Lex.

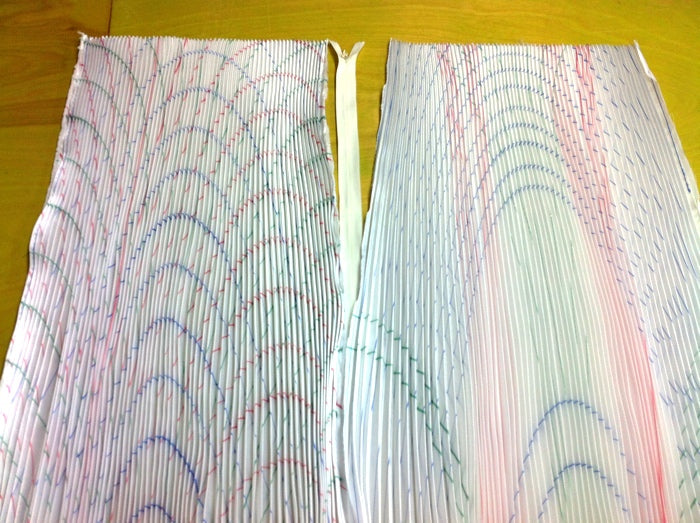

Today the majority of professional pleating is done with the use of large pleating patterns, spanning up to four yards in length. Some of the more complex patterns can take several months to complete, before they are even ready to be used for fabric pleating. Certain types of irregular pleating can only be done with the use of a pattern. For example, sunburst and combination pleating have to be done using a pattern. Below is an example of an accordion and herringbone (or chevron) combination pleating pattern.

3. Machine Pleating – There are several different ways these machines can be built to accomplish the task of pleating. The machines we use at our factory have long blades that pinch the fabric across the entire width and then fold it. Generally speaking, machine pleating is the least expensive method when making simple pleats like side pleats, box pleats or crystal pleats because they require less labor than other pleats. One big advantage of machine pleating is that the entire roll of fabric can be pleated at once and used for a variety of applications. There are other couture type pleats that we make by machine as well. These higher end pleats are usually a combination of two or all of the processes described above. Since the possibilities of mixing different pleating techniques together are virtually infinite, experimenting with them is something we love to do.