What is fusible interfacing?

Fusible is basically a fabric with adhesive on it. It is used as a backing for the purpose of stability, or for adding body to the fabric. There are several different types of fusible fabrics and they each have a different purpose. Lighter weight fabrics generally require lighter weight fusibles. Some fusibles are woven, some knit, and some are basically made from paper (usually called Pellon). A woven fusible would be used for strength, a knit if you needed some stretch, and a Pellon is just a cheaper option. There is a common misconception that Pellons are used because they are lightweight but that is untrue. Personally, the lightest and finest fusible I have ever used was a knit fusible made in France.

The most common use of fusibles in garment construction is when it is applied to the facing of the garment. Again, this is to give the garment a bit more stability and shape, especially when the garment is on the hanger (aka hanger appeal). We use fusibles mainly for three applications: wool boucle jackets, inside any structured gown and of course…with our pleating.

This brings us to the real point of this post. Why do you fuse pleated fabric? The answer is for stability. There is a huge difference in stitching pleated fabric after it is fused. Depending upon your application, fusing can change your project from a difficult task to one of the simplest fabrics to work with. Below are some pictures of fused pleats:

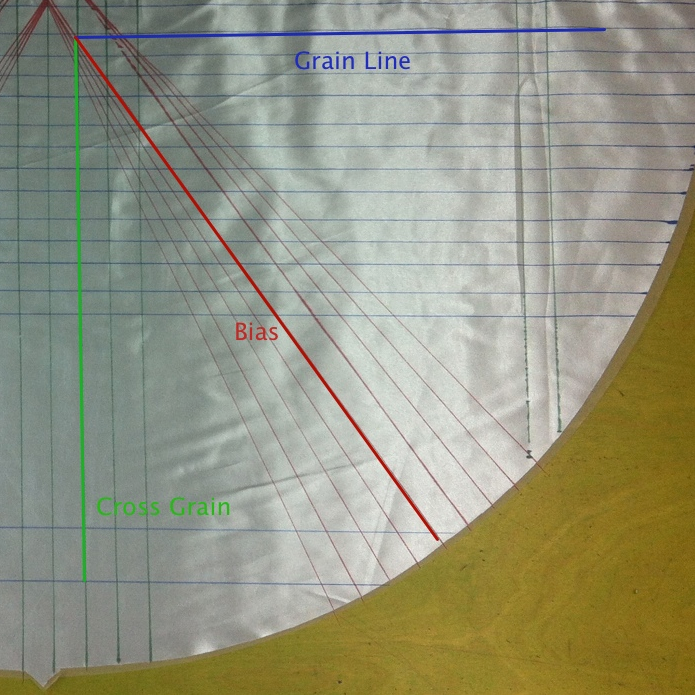

Above: Fused pleating with Pellon fusible.

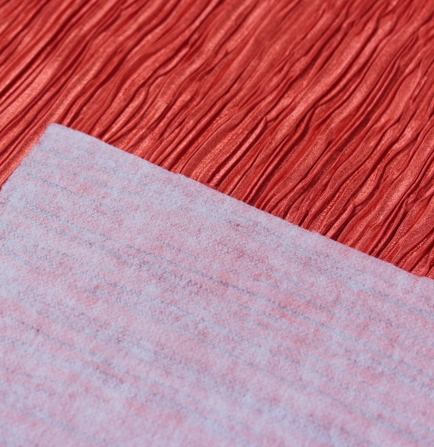

Above: Fused pleating with weft fusible.

This is just a quick summary of fusibles. Of course, I would not recommend fusing in couture type garments, but fusing is great for jackets, pillows or pleated fabric walls. If you want a deeper explanation of types and uses, just email us and I will be happy to answer your questions..